At first, it look realy great and more professional than my old Cupcake ;-)

I like the build size (8x8), the closed chamber, the built-in light and all the promises....

As stated on the website : [...]As a true plug-and-play machine, the Press is the ideal printer for users new to 3D printing. [...] The Solidoodle Press is a one-touch 3D printer designed to fit in your home. A consumer machine with no manual calibration required to get started. Just take it out of the box and start printing]

FALSE !

Installing soliPrint software on windows is easy but not enough : Printer not detected ... Look that on Windows 8.1 you need to install the serial driver too.. Why do I need to search deep on the website to find that ? Put the driver on the same page as the software, it will help everyone.

Good, now, software can talk to the printer but you need , each time, to select your printer from the list of....one printer. It's cool to be able to connect more than one printer but if only one is connected, please use it.

Heating the extruder is fast compared to the bed who took about 15 minutes to reach 100C. It's not a big deal since it's working !

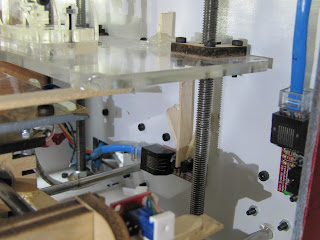

One big probleme now is that the extruder cable go on the way, blocking the X to reach the end-stop and sometimes block also the Y axis. Some users install a rubber or spring to retain the cable. On my side, I only keep the cable no the right side of the extruder before cloing the cover, this keep it from going at the wrong place.

Now, the worst part :

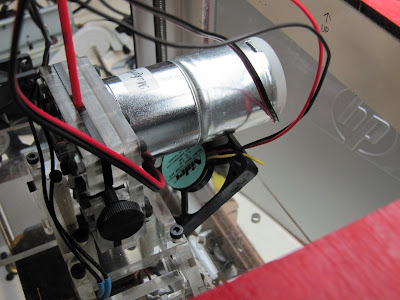

When you try to manualy extrude plastic, a knocking sound come from the extruder and the filament is not extruded consistently.

I turn extruder temp up to 230C and now bumping sound stops. Cool ! Now it should be good !

NO ! :-(

Nothing stick to the plate...

I did the z-offset calibration and even that is not working. Try with AirSpray, blue tape and glue stick. Cleaned every time with Acetone but nothing.

With the bed at 100C and the extruder at 230C + 2x glue stick on the plate I can have a part of something.

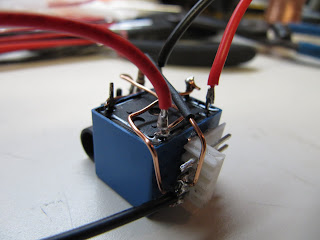

But again sometime I have the bumping sound from the extruder. Remember me some past fail with my CupCake when the motor do not have enough power.

So, enough for now.

Next steps :

- Try to level the bed corectly.

- Adjust the trimpot

- Contact Solidoodle

- Print with kapton tape on the bed